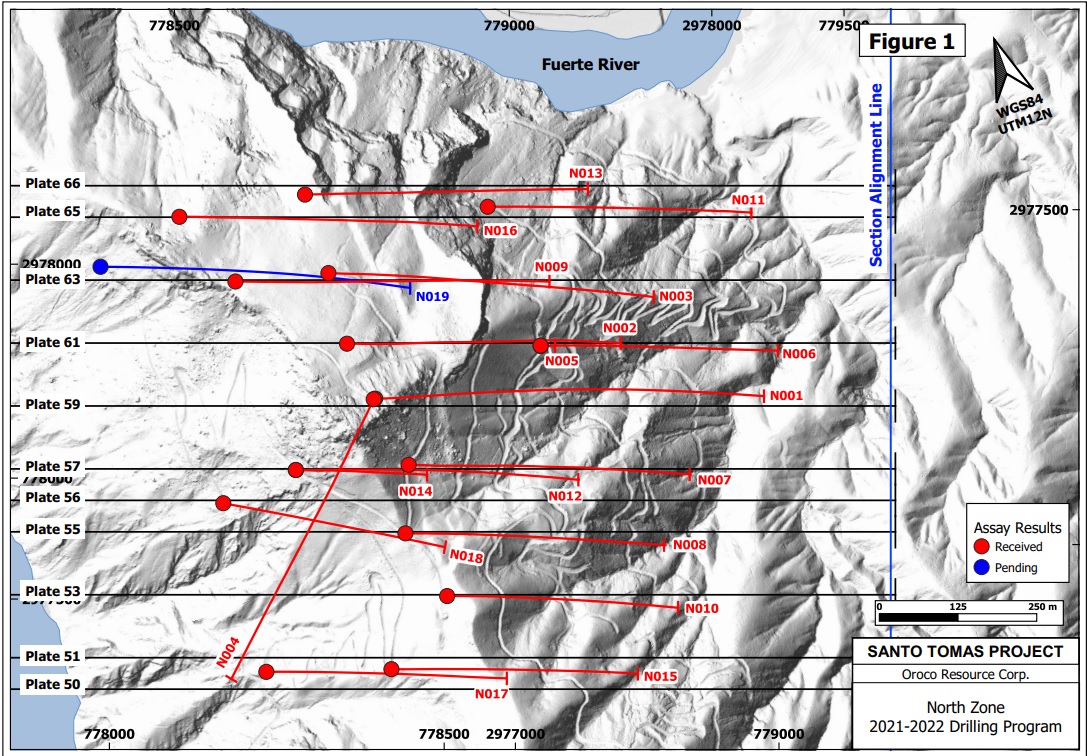

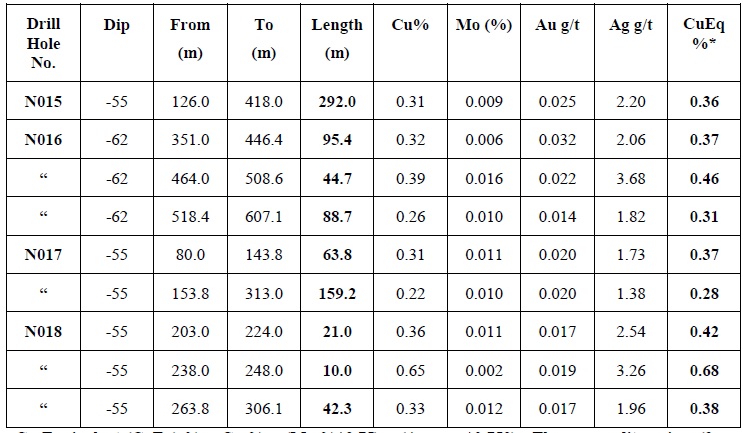

Oroco Resource Corp (OCO.V) has released more drill results from the ongoing drill program on its Santo Tomas copper project in Mexico’s Sinaloa state. The update contains the assay results from four holes N015 to N018 which were all drilled on the North Zone. While the grades encountered in the core were nothing spectacular (as you can see below, they were just boringly consistent – which is good), the important element in the update was the location of the holes.

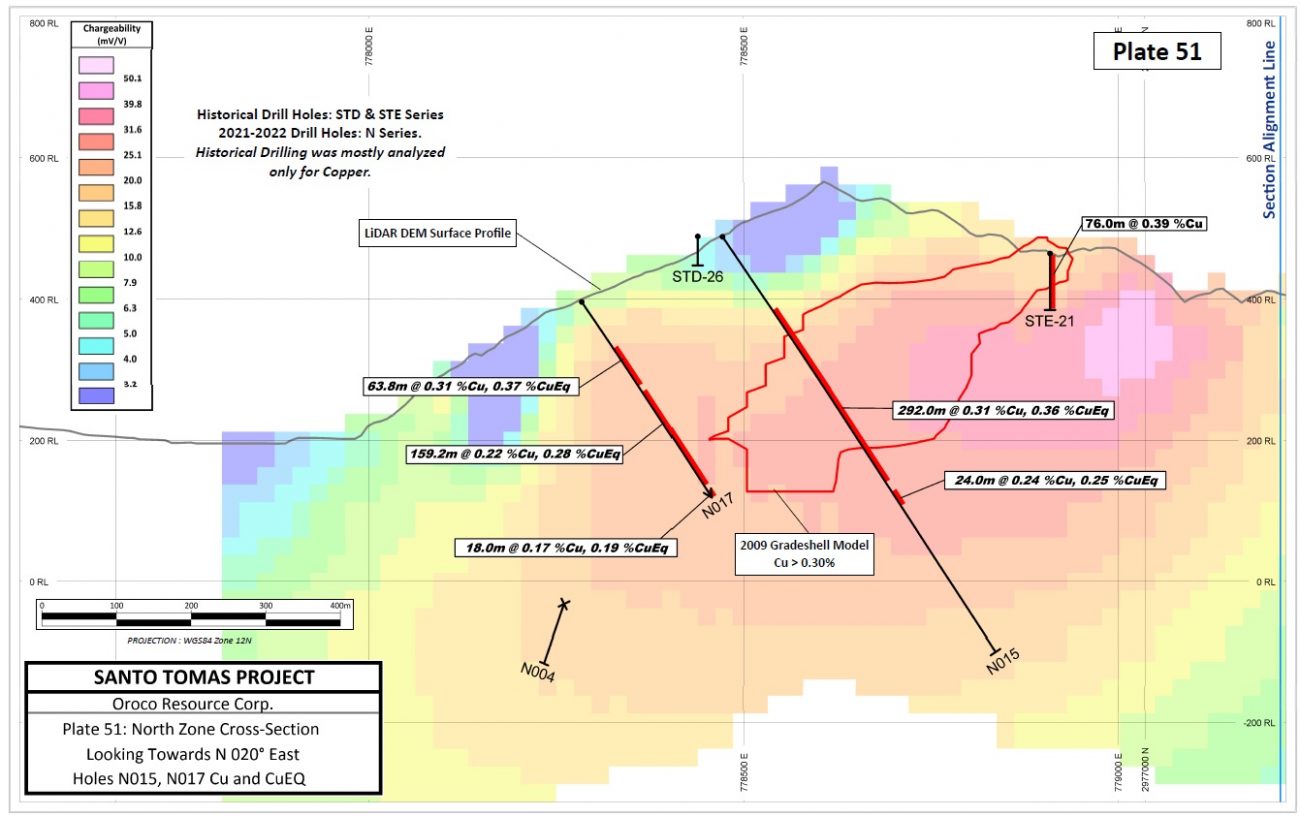

Hole 15 for instance was drilled straight through the historical grade shell, as you can see below. With a continuous interval of just under 300 meters containing 0.36% copper-equivalent the grade isn’t spectacular but the cross section below shows two important take-aways: the mineralization appears to be slightly thicker than anticipated in the grade shell as the copper mineralization started above and ended below the historical grade shell. Even if you’d ignore that final section with 24 meters of 0.25% copper-equivalent (which didn’t even make it into the table of notable intercepts). While the cross section shows the mineralization appears to extend for just a few dozen meters on both sides of the grade shell, this is valuable information. Remember the potential economic viability of a low-grade deposit like Santo Tomas will solely depend on economies of scale. Every tonne that can get mined and processed that doesn’t need to go to the waste dump will add value.

And that’s also why hole 17 is very important. While 65 meters of 0.37% copper-equivalent is okay and the 159 meters containing 0.28% copper-equivalent is on the lower end of the spectrum, this hole does achieve one important thing: it converts waste rock into tonnes that will likely be processed. Sure, at 0.28% copper-equivalent Oroco won’t make too much money on this section. But if the tonnes need to be mined anyway to reach the lower end of the grade shell as part of an optimized open pit shell, then the marginal cost to process these tonnes will be lower than the recoverable rock value. The tonnes will likely be mined anyway (so the mining cost will be incurred no matter what), so then you may as well process it. The downside to this is that although a resource will contain more tonnes, the average grade will be lower as the 0.28% CuEq grade is lower than the anticipated resource grade. But the net trade-off is that these tonnes should be mined and processed.

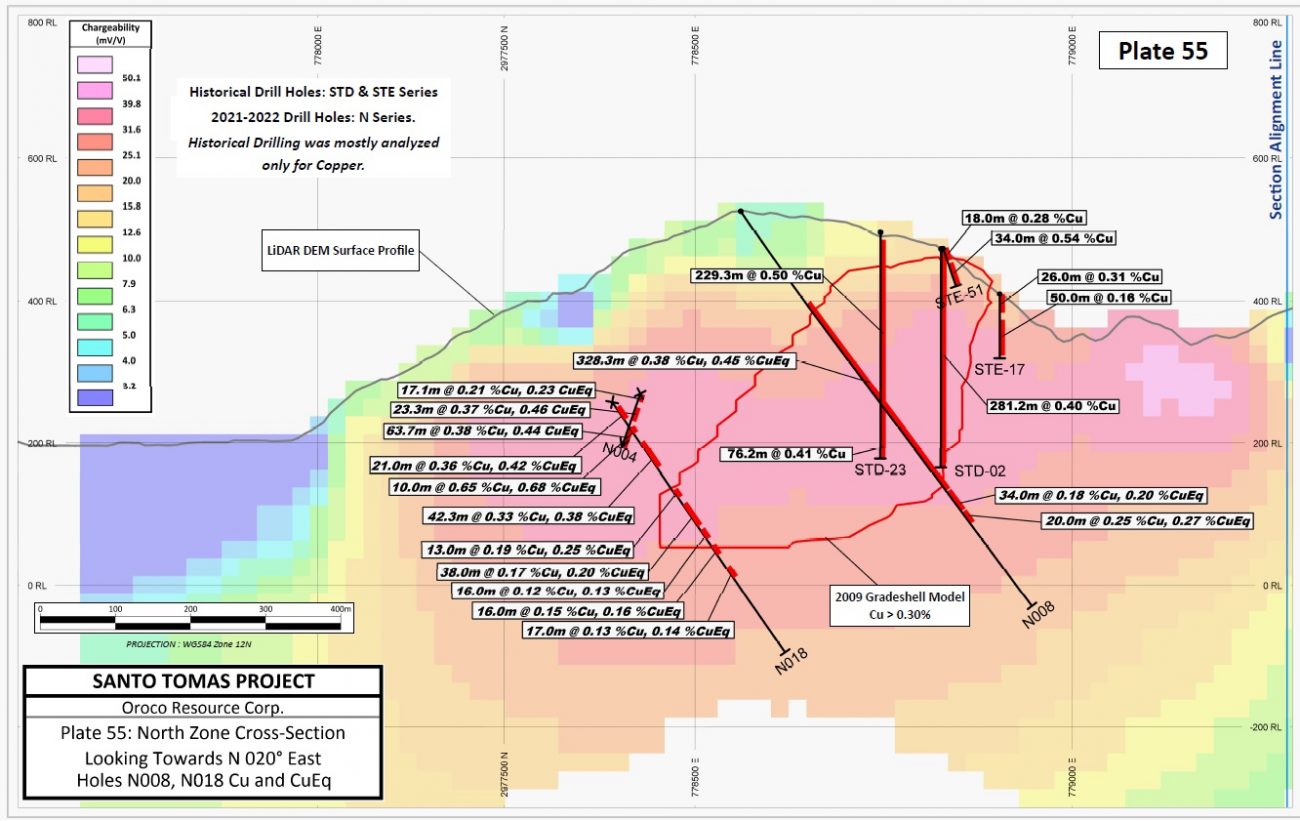

A similar comment can be made about hole 18 (below) but with the added bonus the grade closer to surface is much higher than in hole 17. Intervals of 0.42% CuEq, 0.68% CuEq and 0.38% CuEq will be mined and processed no matter what.

And on top of that, it does achieve the same efficiency boost: a portion of the tonnes outside the grade shell and closer to surface will now no longer be categorized as waste but likely end up in the mine plan.

And that’s what this entire project is about: efficiency and economies of scale. Even a low-grade tonne could add value if it needs to be mined anyway to access a higher grade tonne.

Disclosure: The author has a long position in Oroco Resource Corp. Oroco is a sponsor of the website. Please read our disclaimer.