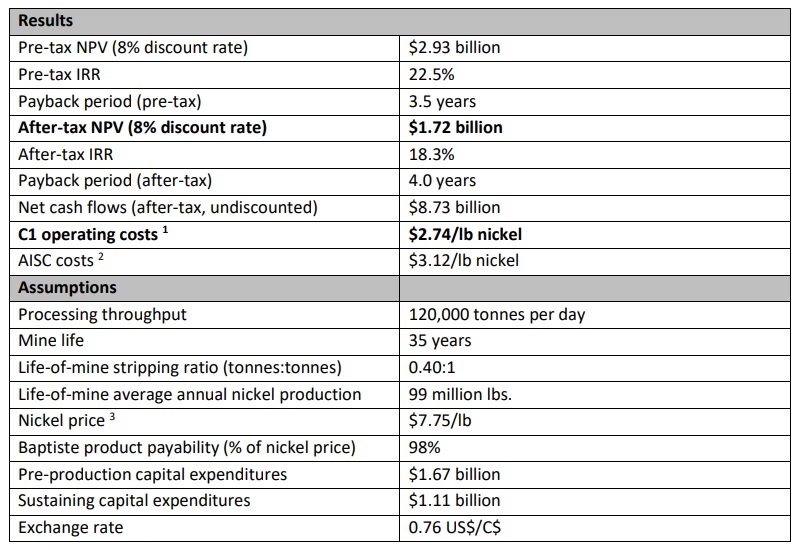

FPX Nickel (FPX.V) recently announced the results of Phase I of a three phase metallurgical test program designed to further advance and refine the flowsheet of the Baptiste nickel project, part of the Decar nickel district.

The results of the first phase seem to indicate the Davis Tube recovery results could be about 5% higher than the 85% used in the preliminary economic assessment on the project, which was completed in 2020. The results are based on testing a 2.4 tonne sample from crushed assay rejects so we should assume the results are pretty reliable.

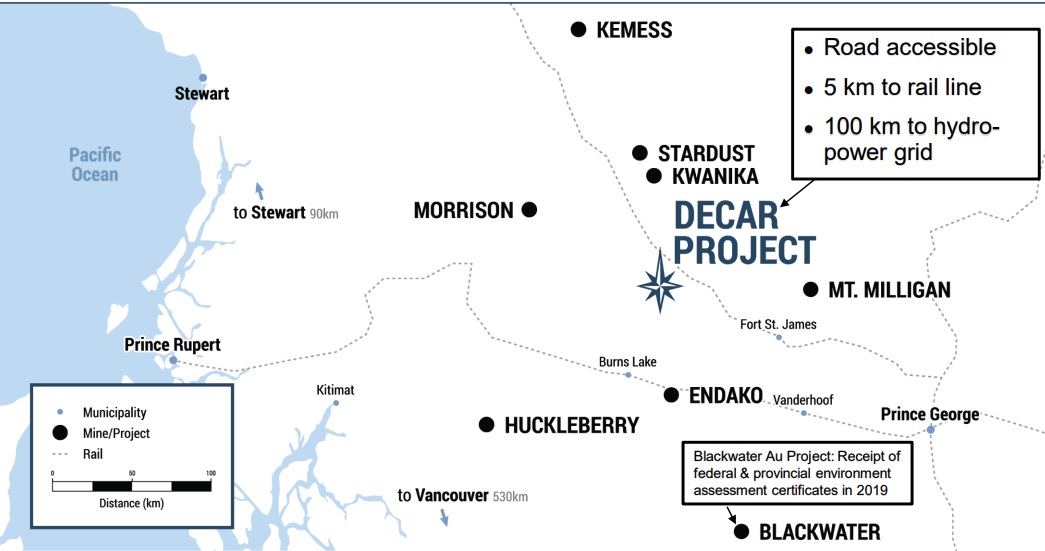

The Phase 2 test work is currently underway and this phase is aiming to further validate and optimize the flotation parameters to confirm the characteristics of the nickel concentrate while the company is also investigating the possibility to produce an iron ore concentrate which would be a useful by-product credit – if the economics make sense as the transportation costs for the iron ore will have to make sense too (although it clearly is positive there’s a railway less than 100 kilometers away). The PEA mentions a potential production rate of 2 million tonnes of iron ore concentrate per year but additional test work is needed as the 61% Fe-grade of the concentrate is just below the 62% benchmark grade. This means the 61% concentrate grade would be ‘penalized’, while the 2020 PEA also mentions high levels of magnesium, silicium and chromite. So there’s some work to do on the iron ore side to make it a viable concentrate.

The subsequent third phase of the metallurgical test program will try to validate the potential integration of the nickel products from Baptiste/Decar in the battery metals supply chain. The results of the second and third phase of the metallurgical test work should be available in Q1 and Q3 2022 respectively.

Disclosure: The author has no position in FPX Nickel. Please read our disclaimer.