Freeman Gold (FMAN.V) has released the results from an updated metallurgical test program conducted on samples from its flagship Lemhi gold project in Idaho. This resulted in an optimized flowsheet with a grind target of 150 microns, a gravity circuit and a 24 hour retention cyanide leaching. This approach yielded a total recovery rate of 97.5% and 96.3% for the two master composites that were sent to the lab.

That’s an improvement compared to previous studies as until now, the flow sheet was using a 110 micron grind size and a 36 hour retention time. Selecting the larger grind size could save about 5-10% of the energy cost in the grinding phase. Additionally, needing just 24 hours instead of 36 hours could reduce the initial capex of the mine as the infrastructure could potentially be resized.

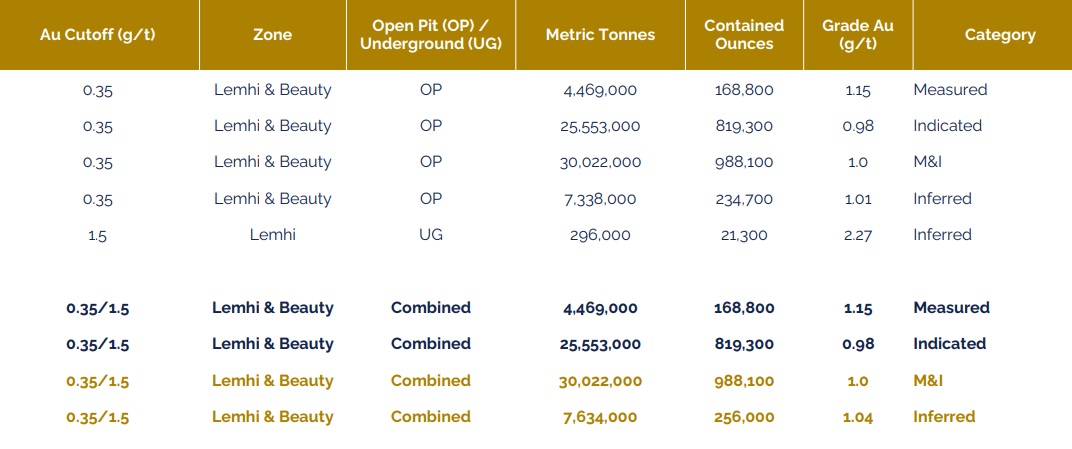

Freeman Gold still expects to publish the results of the Preliminary Economic Assessment on the project later this quarter.

Disclosure: The author has a long position in Freeman Gold. Please read our disclaimer.